How Induction Sealer Secure Your Bottles

The Ultimate Guide to Understanding Induction Sealers for Bottles

Introduction

In the competitive landscape of packaging solutions, ensuring product safety, freshness, and tamper-evident sealing is paramount. An induction sealer is a versatile solution widely utilized in pharmaceuticals, food and beverage, cosmetics, and agrochemicals. As Vietnam’s leading manufacturer and exporter of seal liners and packaging solutions since 2014, Sam Lan provides advanced induction sealing technologies designed specifically for global market demands.

What is an Induction Sealer?

An induction sealer uses electromagnetic induction technology to hermetically bond a foil liner onto the opening of containers such as bottles or jars. This process creates a tamper-evident, airtight seal ensuring product quality, extended shelf life, and consumer safety.

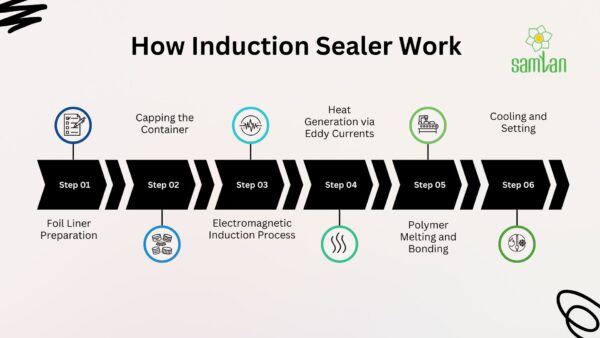

Detailed Explanation of How an Induction Sealer Works

- Foil Liner Preparation: The sealing process begins with a specialized foil liner, typically composed of an aluminum layer laminated with polymer and wax coatings. This liner is placed inside the container’s cap before sealing.

- Capping the Container: After filling the container with product, the cap (including the liner) is placed securely onto the container’s opening.

- Electromagnetic Induction Process: The capped containers pass beneath an induction sealing machine. Here, an induction coil generates a high-frequency electromagnetic field.

- Heat Generation via Eddy Currents: This electromagnetic field induces eddy currents in the aluminum layer of the foil liner. The resistance within the aluminum layer rapidly generates heat.

- Polymer Melting and Bonding: The generated heat melts the polymer layer on the liner, causing it to adhere firmly to the rim of the container.

- Cooling and Setting: Once out of the electromagnetic field, the polymer quickly cools and solidifies, resulting in a secure, airtight, and tamper-evident seal.

Advantages of Using Induction Sealing Technology

- Reliable Product Protection: Prevents leaks, contamination, and extends product freshness.

- Tamper-Evident Security: Provides clear evidence of tampering, boosting consumer confidence.

- Operational Efficiency: Offers fast sealing rates suitable for large-scale manufacturing.

- Material Compatibility: Effective on diverse materials including polyethylene (PE), polyethylene terephthalate (PET), polypropylene (PP), glass, and other substrates.

Sam Lan’s Range of Induction Sealers

- Portable Induction Sealer Machines

Ideal for small-scale production, quality assurance laboratories, and mobile operations, these machines deliver efficient sealing without extensive infrastructure.

- Industrial-Scale Induction Sealers

Engineered for continuous, high-volume manufacturing lines, these sealers seamlessly integrate into existing production setups, delivering consistent sealing quality and efficiency.

Why Partner with Sam Lan?

- Customizable Solutions with OEM/ODM Capabilities

We specialize in tailor-made packaging solutions, adapting induction sealers and liners to fulfill unique requirements and comply with international industry standards.

- Stringent Quality Assurance Protocols

Sam Lan strictly follows internationally recognized quality certifications and rigorous QC processes. Our commitment is backed by robust warranty policies, including refund or product exchange guarantees if quality commitments are unmet.

- Established Global Reputation

Our proven track record includes partnerships with leading international brands. This reputation underscores our reliability, technical expertise, and unwavering dedication to customer satisfaction.

Read more about Sam Lan’s profile

Practical Tips for Using Induction Sealers Effectively

- Correct Container and Liner Matching: Always ensure compatibility between the liner material and the container type.

- Routine Maintenance: Regular inspection and cleaning of induction sealing equipment ensure optimal performance.

- Quality Checks: Regularly test seals for strength and integrity to maintain consistent product quality and safety.

Frequently Asked Questions (FAQs)

- Is induction sealing suitable for all container materials? Yes, induction sealing works efficiently on containers made from PE, PET, PP, glass, and various other materials.

- Are induction-sealed products safe for food and pharmaceutical use? Absolutely. The induction sealing process provides a hygienic, contamination-free sealing solution ideal for sensitive industries such as pharmaceuticals, food, cosmetics, and agrochemicals.

- What factors should I consider when selecting an induction sealer? Consider your production volume, container material, container size, and budget. Sam Lan provides professional consultation to identify the optimal solution tailored to your specific requirements.

Connect with Sam Lan

For inquiries about bulk orders, partnership opportunities, or sample requests, contact Sam Lan directly. Our expert team is ready to support your journey toward advanced packaging solutions.