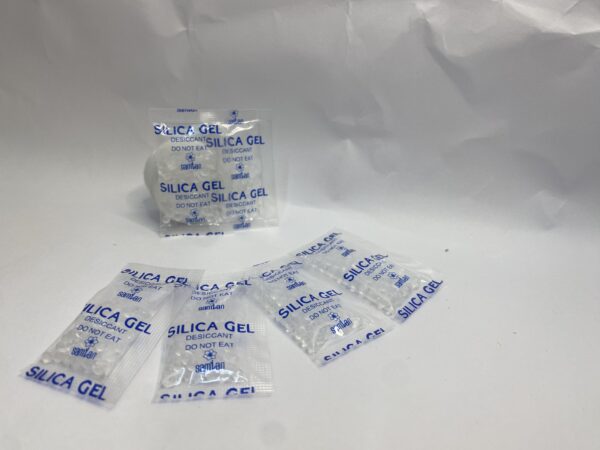

Silica Gel Purpose: Cotton vs OPP vs Mesh Guide 2025

If you’ve ever wondered about silica gel purpose beyond those little packets in your shoe boxes, you’re in for a treat. Today, we’re diving deep into the fascinating world of silica gel types and helping you choose the perfect moisture-absorbing companion for your products.

What Exactly is Silica Gel and Why Should You Care?

Before we jump into comparing different types, let’s get our basics straight. Silica gel is essentially a superhero in the packaging world – a synthetic form of silicon dioxide that’s incredibly thirsty for moisture. Think of it as a tiny sponge that never gets full, constantly working to keep your products dry and fresh.

The primary silica gel purpose is moisture control, but modern applications have expanded far beyond simple humidity absorption. Today’s silica gel solutions protect everything from electronics and pharmaceuticals to food products and leather goods.

3 Different Types: Cotton, OPP, and Mesh Silica Gel Packets

Recent industry analysis has shown that effective moisture control solutions are becoming increasingly critical for product preservation across various sectors.

Cotton Silica Gel Packets: The Classic Choice

Cotton silica gel packets are like the reliable friend who’s always there when you need them. These packets use natural cotton fabric as their outer casing, creating a breathable barrier that allows moisture to pass through while keeping the silica gel beads safely contained.

Advantages of Cotton Silica Gel:

- Superior breathability: Cotton’s natural fiber structure allows excellent air circulation

- Eco-friendly appeal: Made from natural materials, appealing to environmentally conscious brands

- Soft texture: Won’t scratch or damage delicate surfaces

- Cost-effective: Generally the most budget-friendly option for large-scale applications

- Versatile sizing: Available in various dimensions to fit different packaging needs

Best Applications:

- Food packaging (especially dried goods, nuts, and snacks)

- Leather products and shoes

- Textile storage

- Pharmaceutical packaging where gentle contact is important

The Reality Check: While cotton packets excel in breathability, they’re not always the strongest option for heavy-duty industrial applications. The fabric can occasionally tear under extreme conditions, though this rarely affects performance significantly.

Learn more about our premium cotton silica gel packets and their technical specifications.

OPP Silica Gel Packets: The Modern Marvel

OPP (Oriented Polypropylene) silica gel packets represent the evolution of moisture control technology. These packets use a specialized plastic film that’s been engineered for optimal moisture transmission while maintaining superior strength.

Advantages of OPP Silica Gel:

- Exceptional durability: Virtually tear-resistant under normal handling conditions

- Precise moisture control: The film’s engineered pores provide controlled moisture absorption rates

- Clear visibility: Transparent or translucent options allow visual inspection of contents

- Chemical resistance: Unaffected by most common chemicals and oils

- Consistent performance: Maintains effectiveness across various temperature ranges

Best Applications:

- Electronics packaging (cameras, smartphones, components)

- Precision instruments and tools

- Medical devices and diagnostic equipment

- High-value items requiring premium protection

- Export products facing long shipping times

The Trade-off: OPP packets typically come with a slightly higher price point, but the investment often pays off through reduced product damage and longer shelf life.

Mesh Silica Gel Packets: The Heavy-Duty Hero

Mesh silica gel packets are the workhorses of the moisture control world. Using durable synthetic mesh materials, these packets are designed for applications where strength and rapid moisture absorption are paramount.

Advantages of Mesh Silica Gel:

- Maximum strength: Virtually indestructible under normal use

- Rapid absorption: Large surface area allows for quick moisture uptake

- Excellent airflow: Mesh structure provides optimal air circulation

- Versatile materials: Available in various mesh types for different applications

- Reusable potential: Some mesh packets can be recharged through heating

Best Applications:

- Industrial packaging and storage

- Heavy machinery protection during shipping

- Bulk storage containers

- Agricultural product preservation

- Marine and outdoor equipment protection

Considerations: The robust nature of mesh packets makes them ideal for industrial use, but they might be overkill for consumer products where aesthetics matter more than maximum durability.

How to Choose the Right Silica Gel Type

Selecting the perfect silica gel type isn’t just about picking the cheapest option – it’s about matching the solution to your specific needs. Here’s our proven decision framework:

Step 1: Assess Your Product’s Sensitivity Level

- Delicate items (electronics, precision instruments) → OPP packets

- Standard consumer goods (food, textiles) → Cotton packets

- Industrial/heavy-duty items → Mesh packets

Step 2: Consider Your Budget and Volume

- High-volume, cost-sensitive → Cotton packets

- Medium volume, quality-focused → OPP packets

- Low volume, maximum protection → Mesh packets

Step 3: Evaluate Environmental Factors

- Extreme humidity conditions → Mesh or OPP packets

- Temperature fluctuations → OPP packets

- Eco-conscious branding → Cotton packets

Step 4: Think About Aesthetics and Brand Image

- Premium consumer products → OPP packets (sleek appearance)

- Natural/organic products → Cotton packets (eco-friendly image)

- Industrial/B2B products → Mesh packets (professional durability)

Not sure which option fits your needs? Contact our packaging experts for a free consultation and product recommendation.

Latest Industry Trends and Innovations in Silica Gel Technology

The packaging preservation industry is evolving rapidly, and silica gel technology is keeping pace with exciting developments:

Smart Silica Gel Solutions

New indicator silica gels change color when moisture levels reach critical points, providing visual confirmation of protection status. This innovation is particularly valuable in pharmaceutical and electronics applications.

Sustainable Packaging Integration

Manufacturers are developing biodegradable packet materials while maintaining the effectiveness of traditional silica gel. Cotton-based solutions are leading this trend, with some companies experimenting with bamboo fiber casings.

Micro-Encapsulation Technology

Advanced OPP films now incorporate micro-encapsulation techniques that allow for controlled release or absorption of not just moisture, but also other gases that can affect product quality.

IoT-Enabled Monitoring

Some industrial applications now use silica gel packets integrated with sensors that can transmit humidity data in real-time, enabling proactive protection management.

Stay updated with the latest packaging preservation innovations on our company blog.

Real-World Success Stories: Choosing the Right Type Matters Based on Industry

- Electronics Manufacturer Reduces Returns by 40%

A Vietnamese electronics exporter switched from cotton to OPP silica gel packets for smartphone shipments to humid Southeast Asian markets. The result? A 40% reduction in moisture-related returns and significantly improved customer satisfaction.

- Food Processor Optimizes Costs While Maintaining Quality

A snack food manufacturer found that cotton silica gel packets provided identical protection to more expensive alternatives for their dried fruit products, reducing packaging costs by 25% without compromising product quality.

- Industrial Equipment Manufacturer Eliminates Corrosion Issues

A heavy machinery exporter adopted mesh silica gel packets for ocean freight shipments, completely eliminating corrosion problems that previously affected 15% of their shipments.

Making the Investment: Cost vs. Value Analysis

When evaluating silica gel purpose and options, consider the total cost of ownership rather than just the packet price:

Cotton Packets:

- Lower upfront cost

- Moderate protection level

- Good for standard applications

- Best ROI for high-volume, standard protection needs

OPP Packets:

- Higher upfront investment

- Superior protection and durability

- Excellent for premium products

- Best ROI when product value and brand reputation are priorities

Mesh Packets:

- Moderate to high cost depending on specifications

- Maximum protection and reusability

- Ideal for industrial applications

- Best ROI in harsh environments or high-damage-risk scenarios

Conclusion: The Right Choice for Every Application

Understanding silica gel purpose and the unique benefits of each packet type empowers you to make informed decisions that protect your products and your bottom line. Whether you choose the eco-friendly reliability of cotton packets, the advanced protection of OPP solutions, or the heavy-duty performance of mesh options, the key is matching the technology to your specific needs.

Remember, the best silica gel solution is the one that provides adequate protection for your products while aligning with your budget, brand values, and operational requirements. In today’s competitive marketplace, this attention to detail in packaging preservation can be the difference between satisfied customers and costly returns.

Ready to optimize your product protection strategy? The moisture control experts at Sam Lan Co., Ltd. are here to help you navigate these choices and implement the perfect silica gel solution for your unique requirements.